Customized solutions

Some applications require ignition and burner systems whose dimensions, performance, technology or other specifications differ from our usual standards. On request, we manufacture specially adapted ignition systems tailored to your individual requirements or the conditions in place at your plant. Just get in touch with us.

Examples: Industrial burners / Ignition and pilot burners

Here you will find a selection of customized solutions in the field of industrial burner systems as well as ignition and pilot burners, realized by HEGWEIN, a member of the DURAG GROUP.

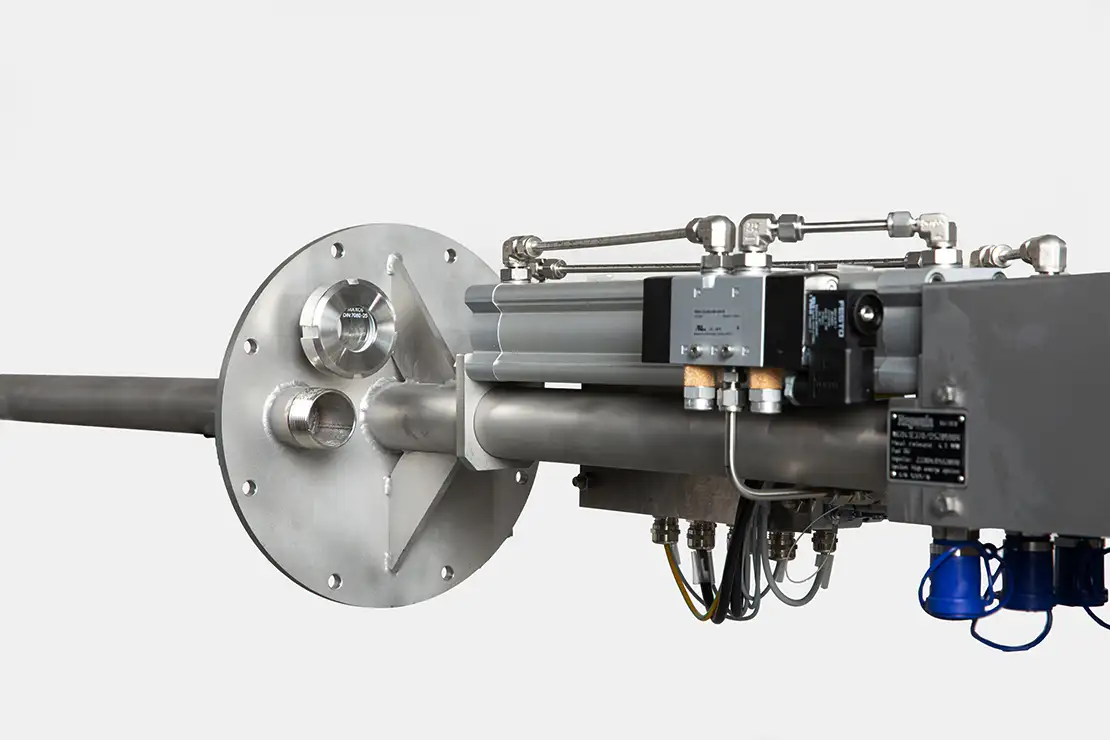

Application: Special solution from HEGWEIN

- Oil ignition, start-up and support burner for use in boiler plants with grate firing system as main firing system

- Delivery of a complete solution (including air fan, gaskets, hoses, cables, plugs, …)

- Project-specific modifications according to on site conditions and requirements

- High combustion chamber temperature

Features:

- Industrial burner design for use in hot combustion chambers with grate firing system as ignition burner and support burner for main firing system as well as start-up burner for boiler heat-up procedure

- Fuel and thermal power: Light fuel oil for 3 MW heat release (240 kg/h light oil)

Scope of supply:

- Burner with combustion air register and oil/compressed air pressure atomizer

- Pneumatic retraction unit for oil atomizer

- Electrical high energy ignition system

- Pneumatic retraction unit for high energy ignition lance tip

- Optical flame monitor

- Combustion air fan

- Accessories (hoses, gaskets, cables, plugs, …)

Click on the image to open the image gallery.

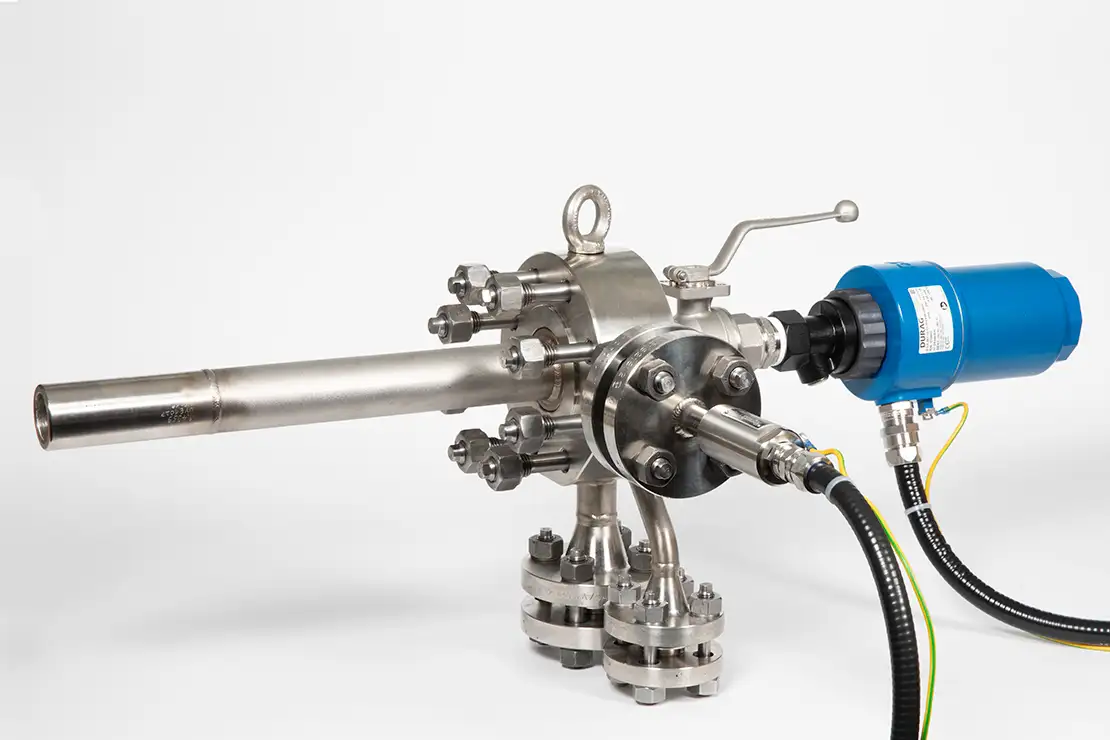

Application: Special solution from HEGWEIN

- WUG (warm-up gun) for oil ignition, start-up and support burner for use with pulverized coal burner

- Integration into existing on-site main burner and connection to preinstalled media supply (oil and air)

Features:

- Industrial WUG design for use in hot combustion chambers with pulverized coal burners as main firing system as ignition burner and support burner mounted at the center in main coal burners

- Start-up burner for boiler heat-up procedure

- Fuel and thermal power: Light fuel oil for 4.5 MW heat release (360 kg/h light oil)

Scope of supply:

- Oil lance with oil/compressed air pressure atomizer, mounting plate and combustion air swirler (flame holder/stabilizer)

- Pneumatic retraction unit for oil lance

- High energy spark ignition system

- Pneumatic retraction unit for high energy ignition lance tip

- Optical flame monitor

- Accessories (cables, gaskets, hoses including quick-release couplings, …)

Click on the image to open the image gallery.

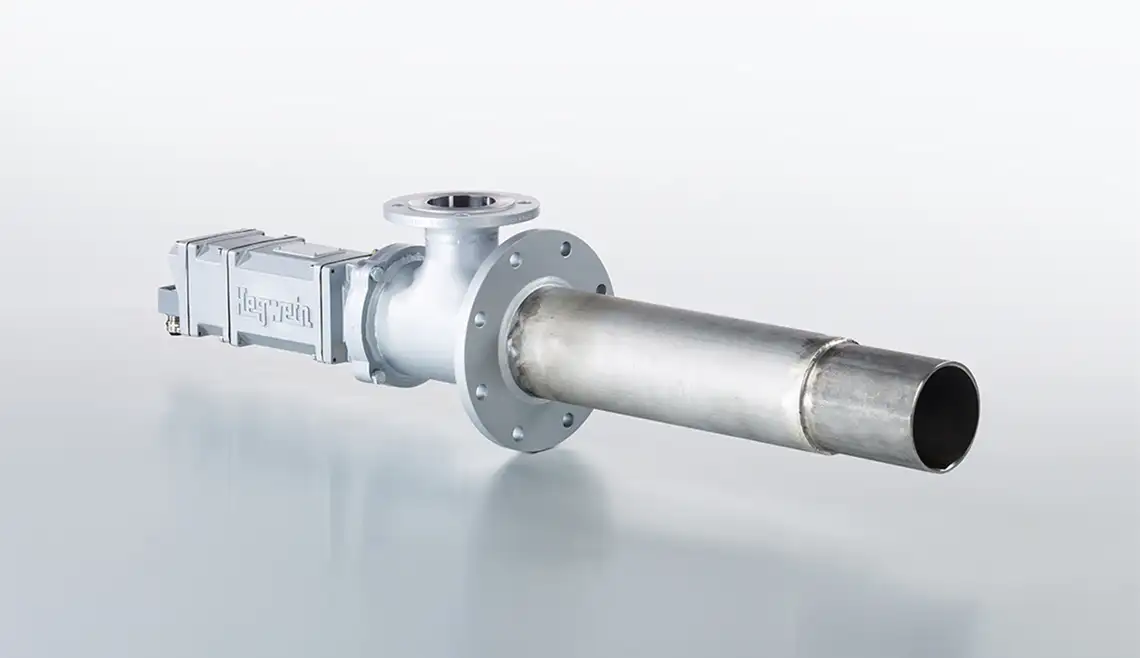

Application: Special solution from HEGWEIN

- High pressure pilot burner for use in coal gasification reactor for hydrogen/syngas (H2 + CO) production

- Hegwein is a well-known supplier of high pressure ignition systems

Features:

- Industrial pilot burner for use in coal gasification reactor with high temperature/high pressure combustion chamber

- Start-up burner for gasification reactor heat-up procedure

- Design pressure: 35 barg

- Operating pressure: 25 barg

- Fuel: Natural gas/methane

- Heat release: 30 kW at atmospheric pressure, 780 kW at 25 barg high pressure

- High energy spark ignition system

- Optical flame monitor

- Explosion protection area: ATEX zone 2

Scope of supply:

- Industrial high pressure gas pilot burner

- Design in accordance with EU Pressure Equipment Directive

- High energy spark ignition system

- Optical flame monitor

- Equipment designed for explosion protection area: ATEX zone 2

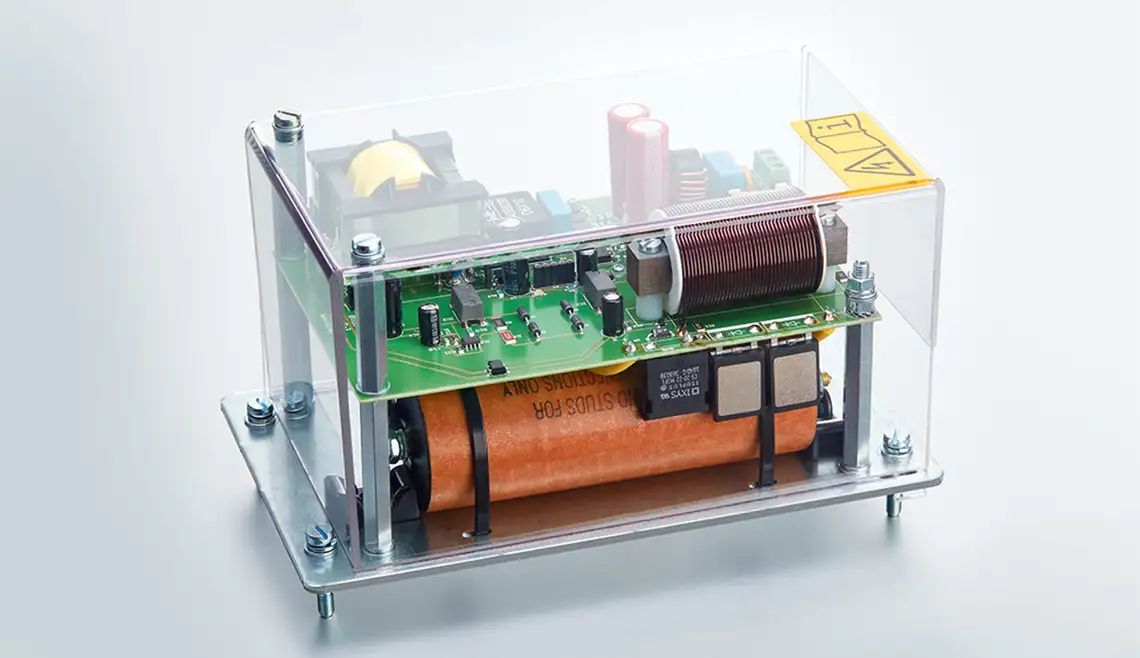

Application: Special solution from HEGWEIN

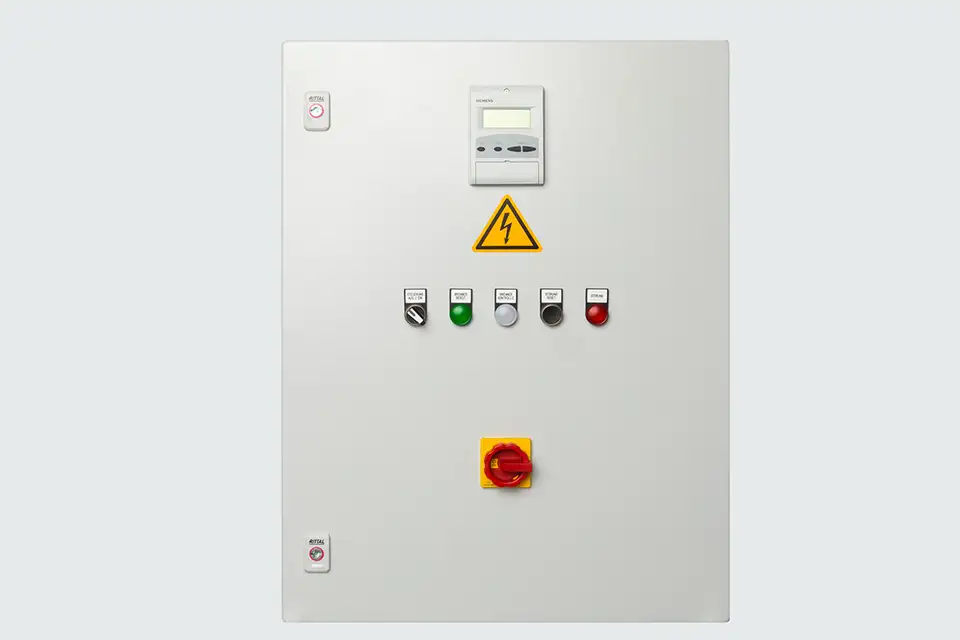

- Industrial gas burner for use in a combustion chamber with 0.5 barg counter pressure with combustion air fan, gas skid, air skid and local control cabinet with burner management and fuel / air ratio controls

- Project-specific design according to customer requirements

- Delivery of a complete solution (including air fan, gaskets, hoses, cables, …)

Features:

- Industrial gas burner for use in high temperature/medium pressure combustion chamber with coal gasification/treatment reactor

- Gas burner for furnace heat-up procedure

- Design pressure: 0.5 barg

- Operating pressure: 0 … 0.1 barg

- Fuel: LPG

- Heat release: 100 kW, control range 1:5

- High voltage spark ignition

- Ionization flame monitor with SIL 2

Scope of supply:

- Industrial medium pressure gas burner

- High pressure combustion air fan, air skid and safety automatic shut-off valve

- LPG gas skid: 2 barg inlet pressure, 0.3 barg operating pressure with safety and shut-off valve

- Accessories

Click on the image to open the image gallery.

Examples: High-energy ignition

Here you will find a selection of customized solutions in the field of high-energy ignition systems, realized by SMITSVONK, a member of the DURAG GROUP.

Application: Small solution from SMITSVONK

Features:

- Flare ignition

- Gas train in wheatear housing for 2 natural gas flare pilot burners with high energy ignition

- Propane back-up in case natural gas is not available

- All piping is 316 SST, gas train with pressure transmitters and pressure control valves

- Explosion proof and suitable for ambient conditions from 50 °C to 40 °C

Scope of supply:

- 2 pilot burners, junction boxes for thermocouple and ignition signal

- High and low temperature ignition and thermocouple cables

- 2-fold explosion proof ignition and control unit

- Gas train and ignition and control unit are mounted in a weather protection cover

Click the image to open the image gallery.

Application: Small solution from SMITSVONK

Features:

- Flare ignition

- Special ground flare with 3 high energy ignition lances

- Due to highly explosive gases, a spark is enough for ignition and no pilot flame is needed for combustion of the gases

- The ground flare is in operation 24/7. Due to the absence of a pilot flame, the spark and power supply are critical

- Ignition units are suitable for continuous ignition. 3-fold ignition unit is provided with a UPS with batteries for at least 12 hours operation

Scope of supply:

- Ignition lances

- Ignition cables

- Ignition and control unit with UPS