Ignition systems

DURAG GROUP ignition systems are used to safely ignite industrial burners at power plant boilers, refinery furnaces, on ships and in other combustion plants. Industrial combustion of all kinds depends on reliable ignition systems, as malfunctions can lead to unplanned shutdown of the plant involving considerable financial losses for the operator.

Many processes in the petrochemical industry require continuous ignition sources to safely ignite the excess gas that occurs from time to time using flare systems or blow-off devices in order to avoid environmental and health hazards.

Our ignition and pilot burners are used to directly ignite fuels such as gases, oils, biomass and coal directly or to support them in operation. These combustion systems depend on reliable ignition and support of ignition, because flame failure would result in immediate shutdown of the process involving considerable financial losses.

To enable long operating times at the associated processes, ignition systems must remain available for long periods without maintenance and under harsh operating conditions. We meet these requirements for safe areas and we also supply almost all ignition systems for hazardous areas with the appropriate approvals required for use in Europe, America and worldwide.

We offer the right ignition system for virtually any industrial application and supply special solutions for burners in power plants, thermal processes, flares and furnaces in refineries and ignition systems for use on ships. Other versions are available according to customer requirements and project-specific adaptations are possible on request.

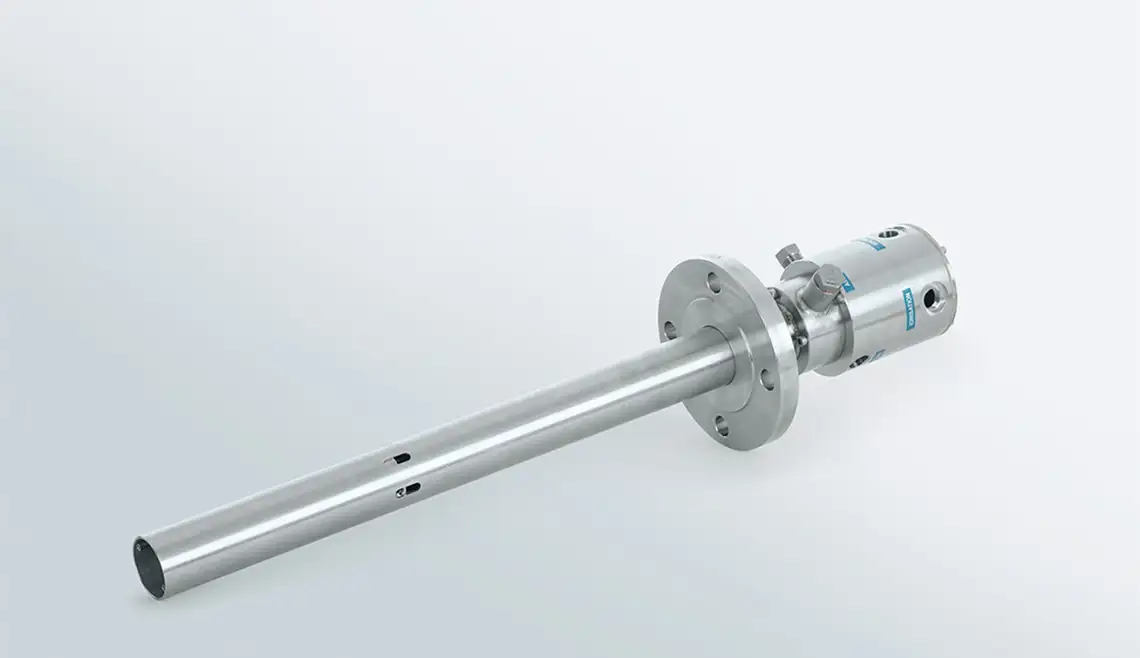

Gas ignition and pilot burners

Gas ignition and pilot burners provide defined, highly-available and stable ignition energy in the form of an ignition flame. They are used to start and stabilize combustion processes and thermal processes for any of the main fuels with variable outputs in different main burner and combustion chamber geometries.

Oil ignition and pilot burners

Oil ignition and pilot burners provide defined, highly-available and stable ignition energy in the form of an ignition flame. They are used to start and stabilize combustion processes and thermal processes for any of the main fuels with variable outputs in different main burner and combustion chamber geometries.

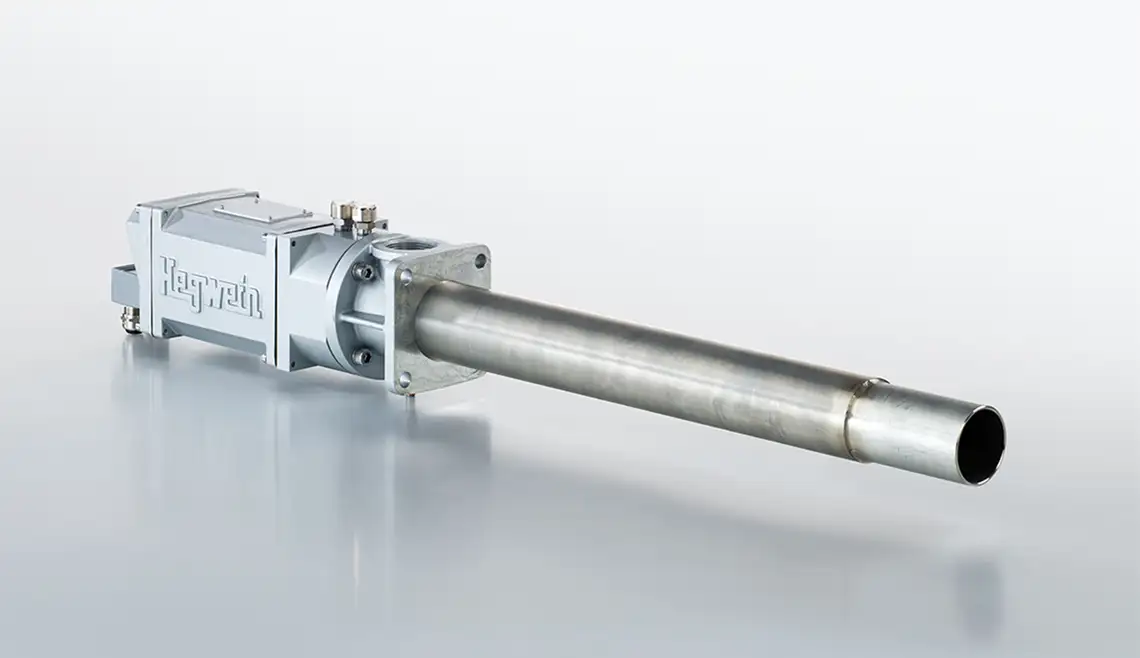

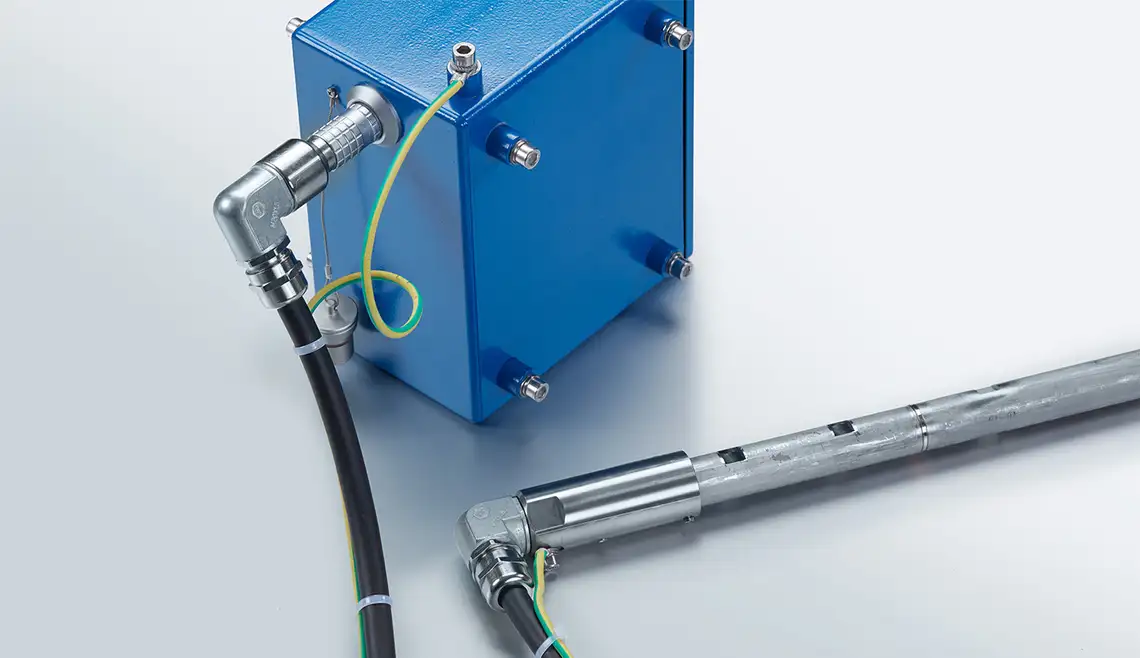

High energy ignition systems

High energy ignition systems are electrical ignition systems for the safe, direct ignition of gas and liquid fuels. In contrast to high voltage ignition systems, they deliver significantly more ignition energy and are less sensitive to moisture and dirt.

The high-energy ignition spark is generated in the high energy ignition device by abrupt discharge of a high-voltage capacitor and then conducted to the ignition tip via the ignition lance or a high-voltage cable.

Optional pneumatic retraction units allow precise and repeatable positioning of the ignition tip to the fuel cone. Retraction of the ignition lance after successful ignition protects the ignition tip from high wear or being destroyed by the flame.

Flare ignition systems

Flare ignition systems are used to ignite the flue gas from pipe flares, air and steam-assisted flares and ground flares. Thanks to reliable ignition and stable burning, pilot burners ensure safe operation of the flare even under the most difficult climatic conditions. In most flare systems, the pilot burner cannot be serviced or replaced while in operation.

Mobile ignition systems

Mobile ignition systems are suitable for the manual ignition of small gas burners or for applications where a pilot burner or ignition burner cannot be installed and simple high energy ignition is not sufficient. The portable or mobile ignition systems are based on integrated high energy igniters and are designed for easy one-man operation. Our mobile models are available as handy trolleys with two or four wheels and can be equipped with up to four standard gas cylinders. All models can be tailored to individual customer requirements.