Indonesian refinery optimizes burner operation with DURAG

The Indonesian refinery company Pertamina relies on DURAG GROUP technology: In its refinery in Balikpapan, located on the Indonesian part of the island of Borneo, the DURAG furnace camera D-FS 50 with video, thermography and analysis system D-VTA 200 has been in use since the end of 2019.

At a glance

| Customer: Pertamina, Indonesia Industry: Refinery, petrochemical industry Application: Monitoring of flame distribution and heat radiation in boilers of a utility power plant Products: Furnace camera D-FS 5, video and thermography software D-VTA 200 |

Optimizing boiler performance with video thermography solutions

Like many users of industrial incinerators, Pertamina faces the challenge of achieving maximum efficiency in electricity production and optimizing the effectiveness of power generation and the use of different fuels. It is important to ensure that the heat inside the boiler is sufficient for the required output and is evenly distributed to prevent damage to the boiler.

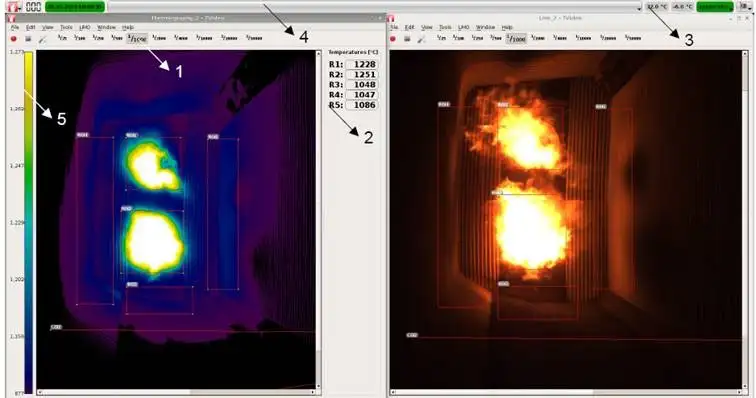

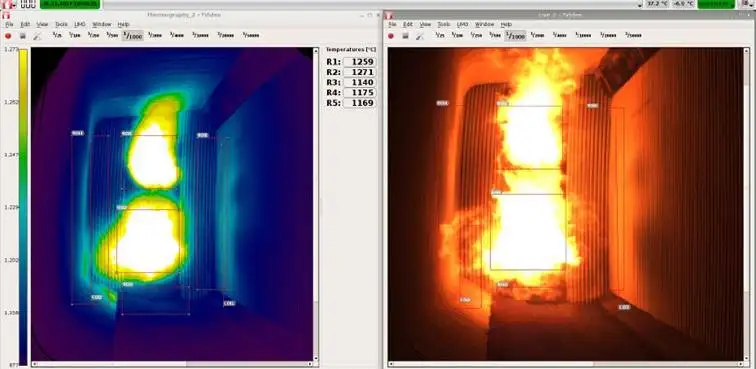

In order to achieve optimum performance of the boiler, Pertamina had requested that furnace cameras be installed for all boiler chambers. These cameras should show the flame distribution (imaging) and heat radiation (thermography) in relation to the boiler burners, tubes and the temperature distribution within the furnace. DURAG has the right solution for this with the combination of D-FS 50 and D-VTA 200.

This combination also meets other requirements:

- Suitable for hazardous areas with the classification ATEX Zone 2

- Temperatures in the combustion chamber of up to 1,600 °C

- Designed for a wide view into the combustion chamber, for analysis of flame length, shape and distribution.

- Suitable for boilers which burn any kind of fuels

The result: fuel savings and optimized burner operation

Within a few weeks of commissioning, the customer achieved fuel savings and optimized operation of the burners. The more stable flame formation also resulted in a reduction in maintenance requirements.

All six boilers were equipped with a video thermography system

In brief: Pertamina is an Indonesian state-owned oil and gas company. In Indonesia's largest refinery with about 1 million barrels of oil per day, there are six boilers for steam generation. In order to increase the efficiency of these boilers and to avoid tube ruptures, DURAG video and thermography systems are used. All six boilers were equipped with a DURAG video and thermography system. Special requirements for explosion protection apply on the refinery site. A DURAG system was supplied for use according to ATEX Zone 2.

The application is described in detail in this whitepaper.