Sustainable energy use thanks to HEGWEIN pilot burners

A newly developed pilot burner system from Danish manufacturer Sirius Energy uses HEGWEIN‘s pilot burner and consumes just three kilos of wood pellets instead of 400 liters of heavy fuel oil per startup.

At a glance

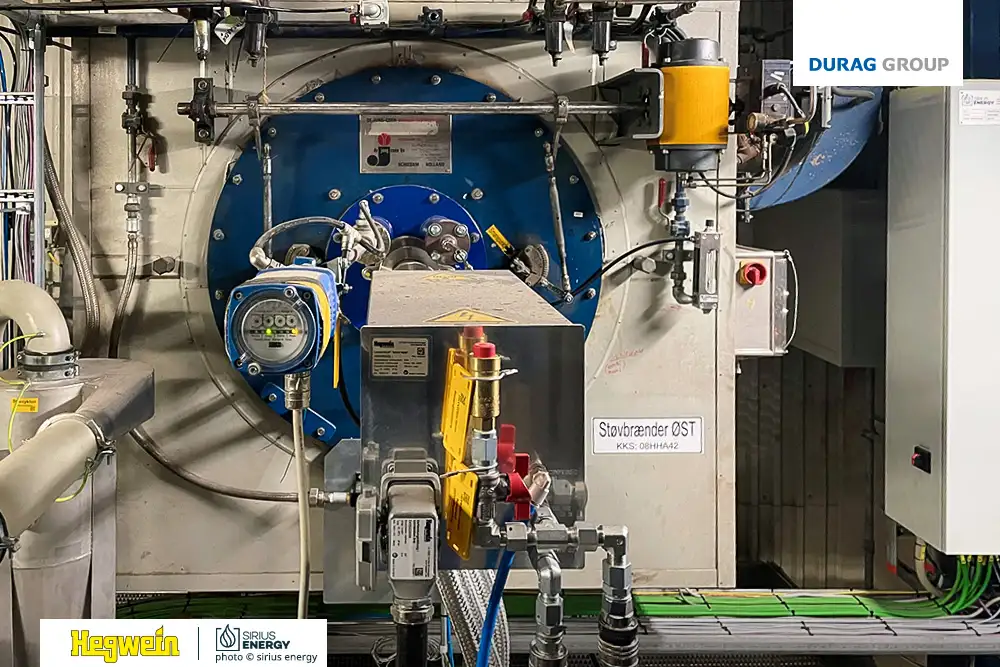

| Customer: Sirius Energy, Denmark Industry: Sustainable energy generation, energy generation from (wood) waste Application: Conversion of pilot burner from oil-fired to wood-dust combustion Products: Plasma igniter and wood dust burner by HEGWEIN and flame monitor by DURAG |

Starting combustion with wood pellets instead of heavy oil

A new, specially developed pilot burner replacement solution from the project manager of Sirius Energy uses the plasma enhanced pilot burners from HEGWEIN. As a result, only around three kilos of wood pellets are required per startup instead of 400 liters of heavy oil at the first site of operation, the VEKS combined heat and power plant in Køge (Denmark). The other advantages are also considerable: the bottom ash is no longer considered as contaminated as it was before due to the presence of oil. Since commissioning in October 2022, the availability of the system has been 100 percent. The VEKS plant is connected to a larger district heating system. The fuel operating costs of the new Sirius/HEGWEIN solution are about one tenth compared to a similar solution using oil.

The Danish plant has a feed grate system that burns wood waste to generate heat, and two wood dust burners that use waste from a saw mill. Originally, the 50-megawatt plant had two fossil fuel-fired start up burners for wood waste and wood dust. Disadvantages included unreliable startup and high oil consumption and corresponding overall costs.

The road to fuel conversion began with a test plant at EUROmilling DK in May 2021 by HN Miljoudvikling and Sirius Energy. There, tests were carried out with the fuel processing system, swirler design and different burner lengths, which allowed individual optimizations to be made for the plant. All parties involved were in constant contact with HEGWEIN about their goals and results.

Finally, the actual order was placed with the DURAG GROUP in January 2022, two completely new systems were delivered, commissioned and have been fully accepted since October 2022. Thanks to this solution, the fossil firing era with heavy oil and gas is history at VEKS. For more information about Sirius Energy, click here: https://siriusenergy.dk/english/

Click on the image to open the image gallery.