Product Filter

Features

- Continuous dust measurement

- Smallest certified measuring range 0 … 7.5 mg/m3

- Single-sided installation without optical alignment

- Automatic check functions

- Continuous, integrated purge air monitoring and control

- Maintenance and linearity check without disassembly

- Contactless measurement

Benefits

- Suitable for official emission monitoring

- Reliable measurement of small dust concentrations

- Space-saving and easy installation

- Long life time and high availability under extreme plant conditions

- Low maintenance

Applications

- Emission measurement of dry flue gases at the stack

- Temperatures up to 600 °C

- Corrosive flue gases, plants with complex gas matrix

- Measurement of dry process gases with small concentrations

Technical Data

- Technical data

- Explosion protection

- System components

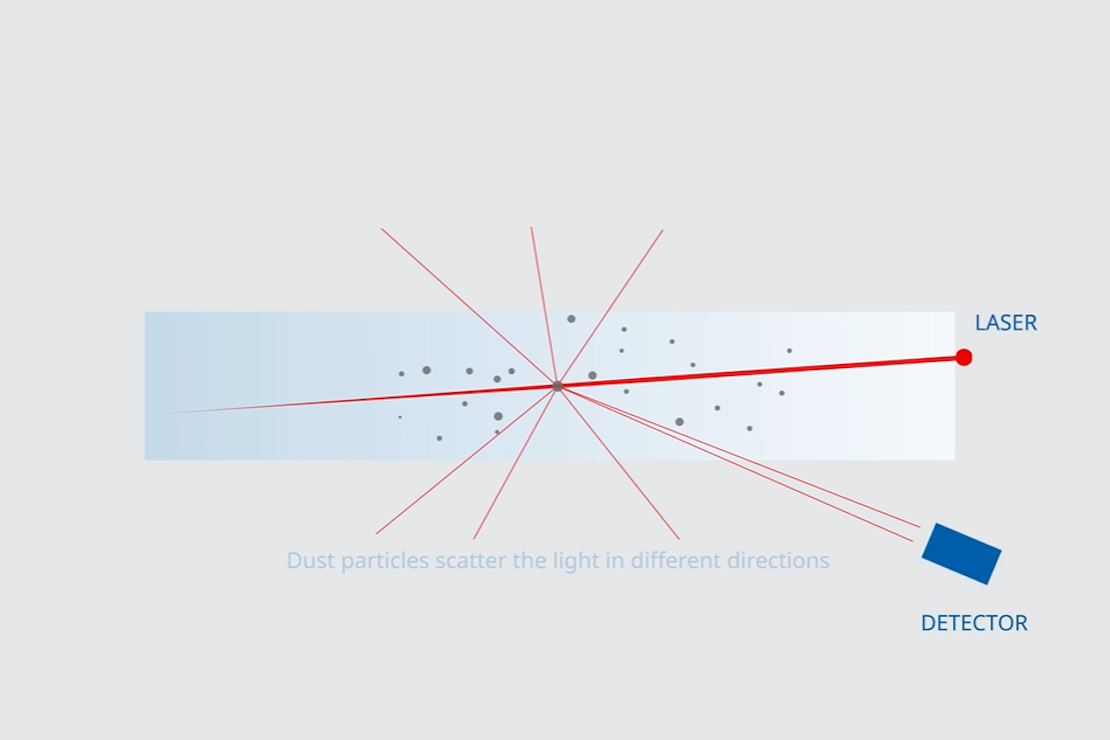

| Measuring principle | Backward scattering, single-sided installation, contactless and in-situ measurement |

|---|---|

| Measuring variable | Stray light units, calibratable as dust concentration in mg/m³ |

| Measuring range | Minimum 0 … 5 mg/m³Maximum 0 … 200 mg/m³ |

| Certified measuring range | 0 … 7.5 mg/m³ |

| Ambient conditions | Installation location: Indoor or outdoor installation**Temperature: -40 … +60 °C-30 … +60 °C (ATEX)-20 … +60 °C (IECEx) |

| Operating conditions | In duct:Temperature: Maximum 600 °CRelative humidity: 0 … 95%, non-condensingRelative pressure: -50 … +50 hPa -50 … 0 hPa (ATEX/IECEx) |

| Dimensions | Inner duct diameter: Minimum 0.7 mWall thickness: Maximum 0.56 m |

| Interface* | Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable)Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC), 0.5 A (various parameters adjustable)RS 485 Modbus RTU, USBStatus display: LED |

| Operation and display | Software D-ESI 100*** orOperating unit D-ISC 100 |

| Check functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation, integrated purge air monitoring and control |

| Protective functions | Integrated fail-safe shutter (optional) |

| Light source | Laser, class II, < 1 mW at 650 nm |

* Additional interfaces with D-ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, PC with Windows operating system required

| ATEX | II 2G Ex px op is IIC T4 GbII 3G Ex pz op is IIC T4 GcII 3D Ex pD III T70 °C Dc |

|---|---|

| IECEx | Ex pzc IIC T4 Gc |

| Dust monitor D-R 320 | |

|---|---|

| Software D-ESI* | |

| Terminal Box with purge air unit D-TB 200 or | |

| Terminal Box without purge air unit D-TB 100** or | |

| Operating and purge air unit D-ISC 100 P |

* Enables remote access via web interface, PC with Windows operating system required

** External purge air supply required

USP

- Patented design, without alignment of optical components after installation

Accessories

- Mandatory

- Recommended

| D-TB x00 |

| D‐ESI 100 |

| D-ISC 100 xx2 |

Downloads

Declarations of Conformity

- Declaration EU D-R 320 M xB1-xx xAx / DE-EN

- Declaration EU D-R 320 M xB1-xxxFx / DE-EN

- Declaration EU D-R 320 M xB1-xxxGx / DE-EN

- Declaration EU D-R 320 M xB1-xxxKx / DE-EN

- Declaration UK D-R 320 M x-B1 / EN

- Declaration UK D-R 320 M xB1-xxxFx / EN

- Declaration UK D-R 320 M xB1-xxxGx / EN

- Declaration UK D-R 320 M xB1-xxxKx / EN

- Declaration US EPA D-R 320 / EN