Features

- Certified for the range of 0-7.5 mg/m3 the lowest range achievable for a dust CEMS (Continuous Emissions Monitoring System)

- Certified and approved dust analyzer for ensuring plant compliance with international standards for industrial emissions

- New: ATEX & IECEx certified to operate safely in hazardous environments, minimizing the risk of ignition and explosion

COMPLIANCE & CERTIFICATIONS

Certifications

- TÜV certified to EN 15267-1:2009, EN 15267-2:2009, EN 15267-3 :2007, EN 14181 :2014

- QAL1 as defined by EN14181

- QAL3 compliance to EN14181

- MCERTs certification for "Stack emissions monitoring equipment at industrial installations” – Continuous emissions monitoring systems (CEMS)

- ATEX (optional):

- II 3G Ex ec nC op is IIC T4 Gc

- II 3D Ex op is tc IIIC T100 °C Dc

- IECEx (optional):

- Ex ec nC op is IIC T4 Gc

- Ex op is tc IIIC T100 °C Dc

- US EPA capable as a PM-CEMS or PM-CPMS

- Compliant with US EPA 40 CFR 60 PS 11

Supporting compliance with international environmental legislation, such as:

- America:

- United States:

- Canada:

- Brazil: Brazilian National Policy on Climate Change / CONAMA Resolutions

- …

- Europe:

- European Union:

- Industrial Emissions Directive – Directive IED 2010/75/EU

- Large Combustion Plant Directive (LCP) 2001/80/EC

- Medium Combustion Plant Directive (MCP) 2015/2193

- Emission Trading System (EU-ETS) Directive

- United Kingdom: Environmental Permitting Regulations (EPR), Pollution Prevention and Control (PPC) Regulations

- …

- United Kingdom:

- Asia & Middle East:

- China: Emission Standard for Stationary-source Pollutants

- Kingdom of Saudi Arabia: Executive Regulations for Air Quality

- India: CPCB and SPCB guidelines for CEMS measurements

- …

- European Union:

Benefits

- Advanced measurement accuracy:

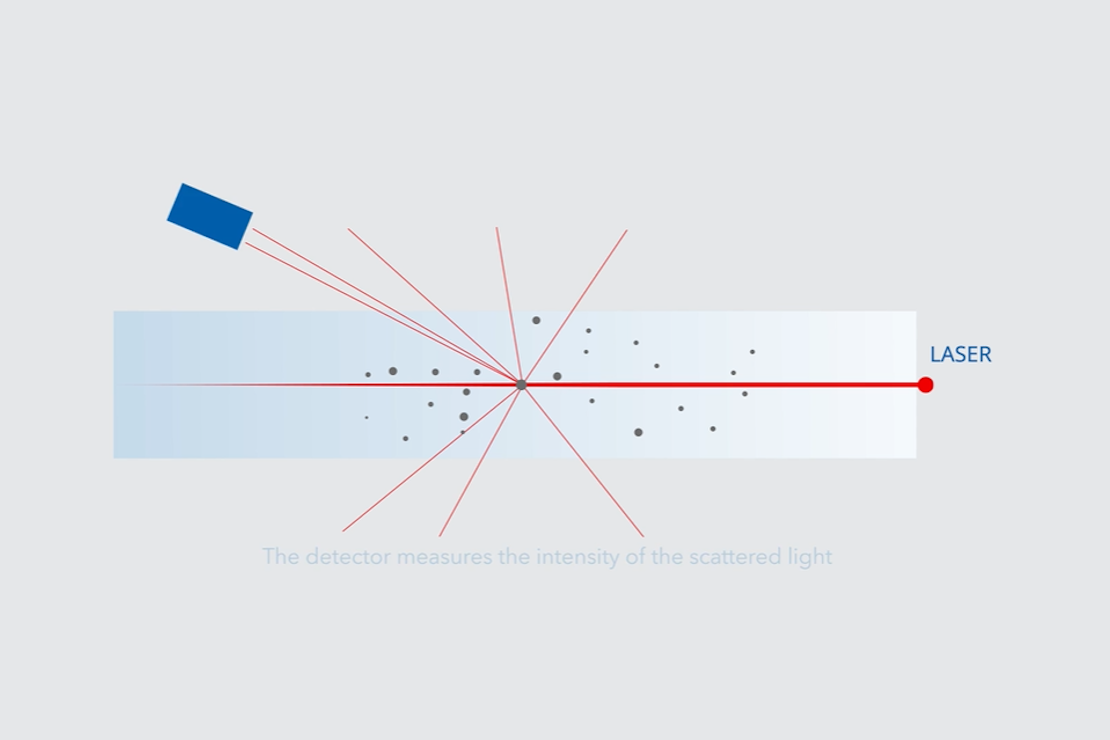

Utilizes forward scattering technology to minimize cross sensitivity to particle type and size - Suitable for high temperature stacks and hazardous Ex zones:

Designed to operate effectively in extreme conditions - Single side installation:

Eliminates the need for optical alignment, making it ideal for thick-walled or double-walled ducts - User-friendly flange:

Easy installation and maintenance; Simply unscrew, turn slightly, and remove the instrument from the stack/duct - Simplified audit process:

Allows for easy verification with manual filters, ensuring consistent and accurate performance checks without removing the device from the stack - Status-dependent indicator light on the analyzer:

Changes color to reflect the operational state of the analyzer, providing clear and immediate visual feedback - Pressure-controlled purge air system:

Ensures that the particulate analyzer remains safeguarded in the event of a blower or plant instrument air system failure - Durable construction with no moving parts in the flue gas flow:

Ensures long-lasting reliability and minimal maintenance - Reduced maintenance and operational costs:

The robust design and minimal maintenance requirements significantly lower the overall cost of ownership and operation

Applications

Typical applications:

Suitable for process applications and for emission compliance for plants equipped with bag filters, cartridge filters, cyclones, electrostatic precipitators, or without any filtration

- Ideal for monitoring non-condensing / dry flue gases

- Monitoring of dust arrestment filter plants

- Monitoring of ventilation systems

Industries:

- Waste to energy plants

- Metal industries, including steel and aluminum production

- Mineral processing, such as cement and gypsum manufacturing

- Chemical industries, including TiO2 production and refineries

- Power generation plants, including coal, gas and biomass plants

Technical Data

- Technical data

- System components

- Explosion protection

| Measuring principle | Forward scattering, in-situ, continuous, single-sided installation |

|---|---|

| Measuring variable | Scattered light units, calibratable as dust concentration in mg/m³ |

| Measuring range | 0 … 300 mg/m³ |

| Certified measuring range | 0 … 7.5 mg/m³ |

| Certificates | QAL1 (TÜV and MCERTS) |

| Standards | IED 2010/75/EU, EN 15267‑1, EN 15267‑2, EN 15267‑3, EN 14181, US EPA 40 CRF 60 PS 11, 13th / 17th / 27th / 30th BImSchV, TA Luft |

| Interface* | Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable)Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC, 0.5 A (various parameters adjustable)RS 485 Modbus RTU, USB |

| Nominal voltage | 24 V– |

| Ambient conditions | Installation location: Indoor or outdoor installation**Temperature: -40 … +60 °C |

| Operating conditions | In duct:Temperature: Maximum 350 °C, optional 500 °CRelative humidity: 0 … 95%, non-condensingRelative pressure: -50 … +50 hPa |

| Dimensions | Inner duct diameter: > 0.3 m (a representative measurement must be ensured)Wall thickness: Maximum 0.47 m |

| Check functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation, integrated purge air monitoring |

| Degree of protection | IP65 in accordance with DIN EN 60 529 |

| Light source | Laser, class 2 in accordance with DIN EN 60825‑1, < 1 mW at 650 nm |

| Connections | Process: Flange, DN 40 PN6 including stud bolts, bolt circle 100 mmDevice: M23 DURAG standardPurge air hose: Ø 25 mmPurge air sensor: M12 8-pin |

| Operation and display | Status display: LEDD-ESI 100 software***or D-ISC 100 operating unit |

| Material | Probe: 1.4404, AISI 316L, polishedHousing: Painted aluminum |

* Additional interfaces with D‑ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, requires PC with Windows operating system

| D-R 808 dust monitor | |

|---|---|

| D-ESI 100 software* | |

| D-TB 200 terminal box | |

| or D-TB 100 terminal box** | |

| or D-ISC 100 P operating and purge air unit |

* Enables remote access via web interface, requires PC with Windows operating system

** External purge air supply required

| ATEX (optional) | II 3G Ex ec nC op is IIC T4 GcII 3D Ex op is tc IIIC T100 °C Dc |

|---|---|

| IECEx (optional) | Ex ec nC op is IIC T4 Gc Ex op is tc IIIC T100 °C Dc |

Accessories

- Mandatory

- Recommended

| D-TB x00 |

| D‐ESI 100 |

| D-ISC 100 xx2 |