HEGWEIN gas burner

Heat release 15 kW to 4.5 MW

Gas burner solutions from HEGWEIN in compact and modular design. Meets local regulations, including hazardous area requirements.

Functionality: Compact design, integrated ionization electrode and ionization flame monitor, integrated ignition electrode and high voltage spark transformer/high energy ignition unit, integrable burner control, fuel-specific gas nozzles, optimized fuel/air mixture and effective flame stabilization at the tube tip.

Features

- Compact modular design

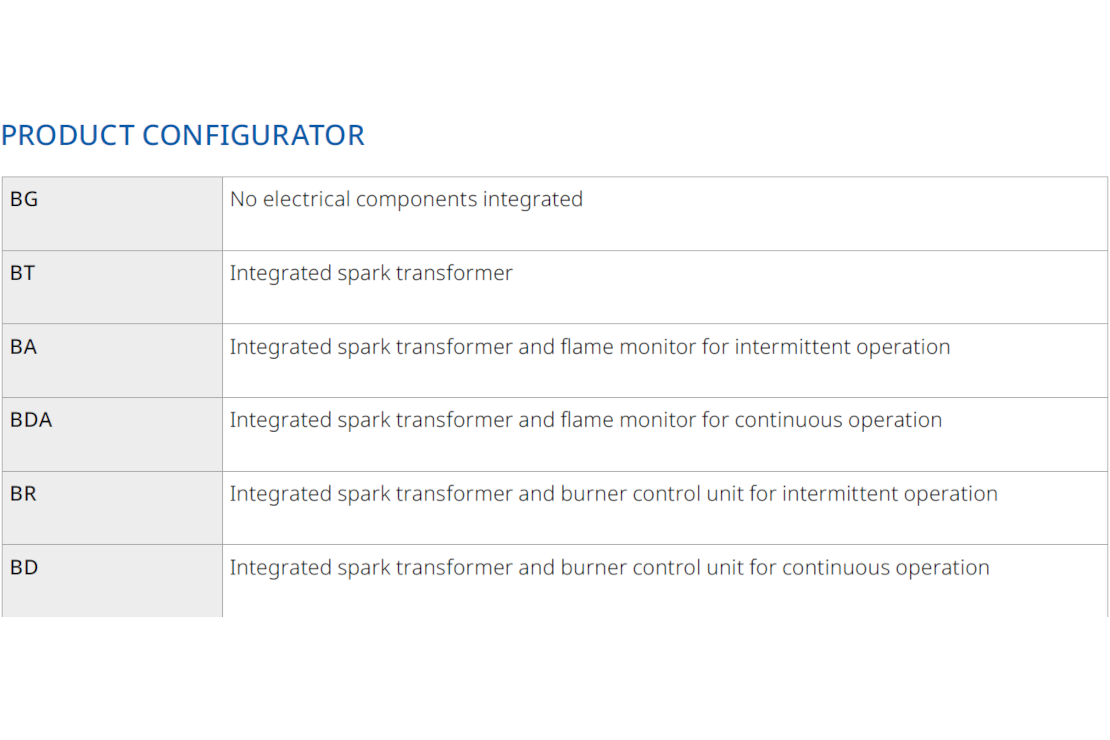

Streamlined for efficient integration - Optional integrated components

Spark transformer, ignition burner, flame monitor, or burner control unit - Electromagnetic compatibility

Optimized for reliable operation in various environments - Simplified setup process

Easy installation and commissioning - Flexible operating modes

Supports one-stage, multi-stage or modulating operation up to 1:10 - High turndown ratio

Enhanced control over performance - Explosion protection

Certified for zone 1/21 and zone 2/22 (ATEX, IECEx, FM-Ex, PESO, KCs, EAC-Ex) - Extensive approvals1

DVGW, AGA, FM, EAC, SIL2/3, and cULus - Customizable versions

Tailored solutions available on request

1 Approval of integrated flame monitor

Benefits

- Fuel flexibility

Compatible with gas fuels of all kinds, such as low/high calorific, mixture of gases, H2, etc. - Robust and reliable

Low maintenance, designed for maximum uptime, suitable for diverse ambient conditions - Integrated ionization or optical flame monitor

“One provider”, cost reduction, ease of integration, enhanced safety and efficiency - Easy service

Electrical and mechanical parts can be replaced independently - Long-term support

Reliable spare parts availability - Customizable tube lengths

Standard lengths up to 4 m, other lengths on request - Wide range of industrial applications

Ideal for chemical, petrochemical, thermal process plants, power plants, etc.

Applications

- For thermal processing systems, fired hot gas generators, furnaces, boiler systems and reactors

- All processes in intermittent operation and continuous operation

Technical Data

- Technical data

| Design | Compact design with ionization electrode, integrated spark transformer, flame monitor or burner control |

|---|---|

| Flame monitor | EU type-approved, SIL 3 |

| Mode | Intermittent operation / continuous operation |

| Supply voltage | 115 / 125 / 230 / 250 VAC |

| Output signal | SPDT contact |

| Protection type | IP54, IP65, IP66 |

| Standard outer tube lengths | From 240 … 4,000 mm |

| Standard outer tube diameter | 35 … 325 mm |

| Nominal heat release | 15 … 4,500 kW |

| Control range | 1-stage, multi-stage or modulating 1:10 |

| Fuel | Natural gas, propane, hydrogen, special gas |

| Gas operating pressure | 20 … 200 mbar |

| Ambient temperature | -40 … +80 °C |

| Explosion protection | Zone 1/21 and zone 2/22 (ATEX, IECEx, FM-Ex, PESO, KCs, EAC-Ex) |

Downloads

General information

- Brochure combustion technology / DE

- Brochure combustion technology / EN

- Infochart hydrogen DURAG GROUP / DE

- Infochart hydrogen DURAG GROUP / EN

- Infochart hydrogen DURAG GROUP / FR

- Industry brochure waste incineration / EN

- Industry brochure waste incineration / DE

- Form accessories for burner systems / EN

- Form accessories for burner systems / DE