- Solutions

- Process and Environmental Monitoring

- Emission and Raw Gas

- Dust Monitoring

Emission monitoring with DURAG's dust monitoring solutions

Dust is an air pollutant from industrial emissions that must be monitored. Dust monitors from DURAG GROUP determine the dust concentration in dry and humid flue gases reliably, accurately and continuously. They are robust, durable and low-maintenance, certified for regulatory emission monitoring and represent the best available technology. In addition, monitoring the dust concentration in raw gases enables the optimization of combustion processes.

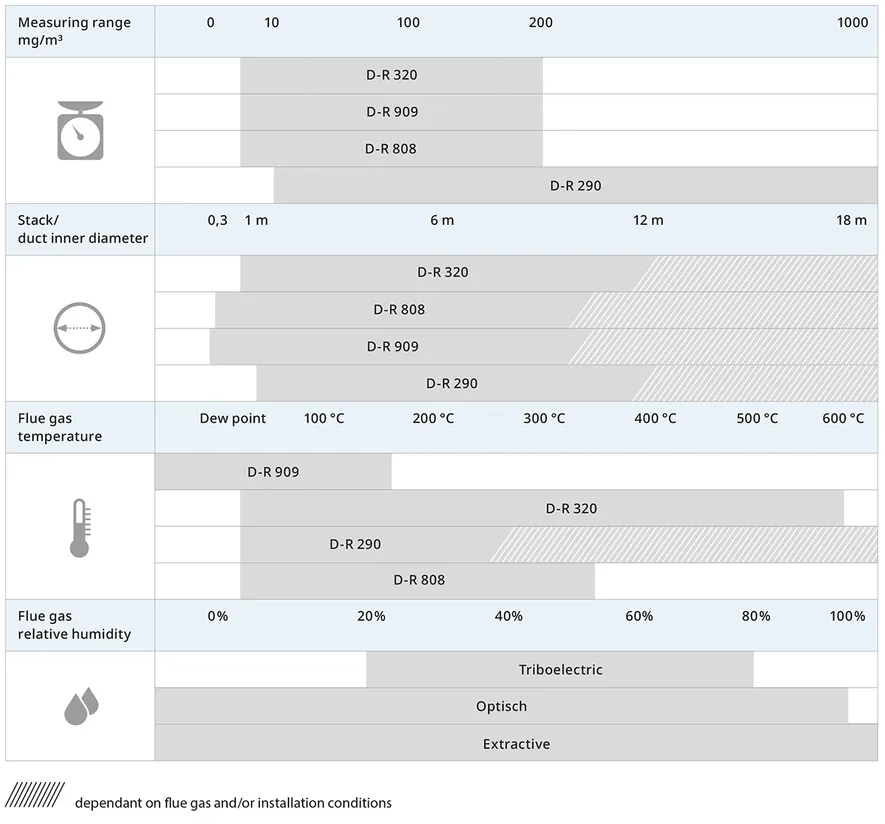

Industrial Dust Monitoring Equipment for Every Requirement

Depending on the requirements and measuring task, we offer various dust measuring systems that use different physical measuring principles. The measuring devices are installed in the flue gas duct, where they measure the dust concentration in milligrams per cubic meter. The measuring device passes this information on to the plant control room for process control. From there, the data is sent to the relevant authority.

Methods and use of our dust monitors compared

D-R 320

D-R 909

D-R 808

D-R 290

Components of dust measurement systems

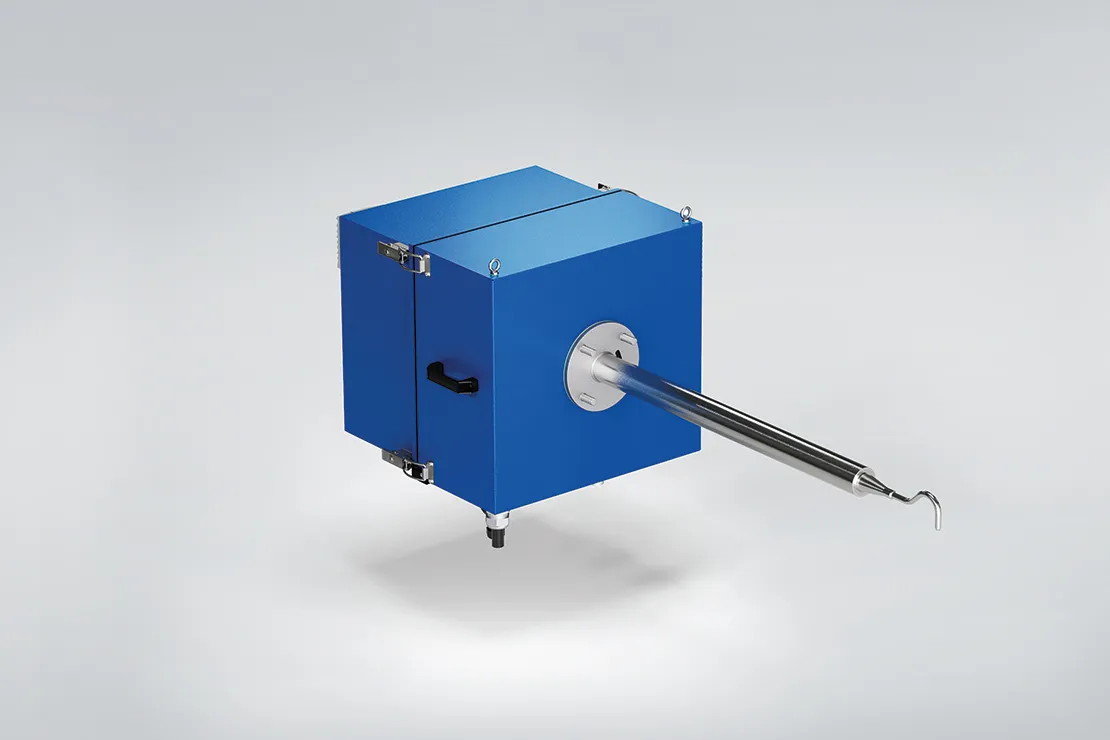

A measuring system for measuring dust concentration consists of a measuring device, a supply unit and various other components depending on the product solution. For example, we supply various solutions for the purge air supply and, where required, an operating unit with a display.

Transmission principle

We use a third party service to embed video content that may collect data about your activity. Please review the details and accept the service to watch this video.

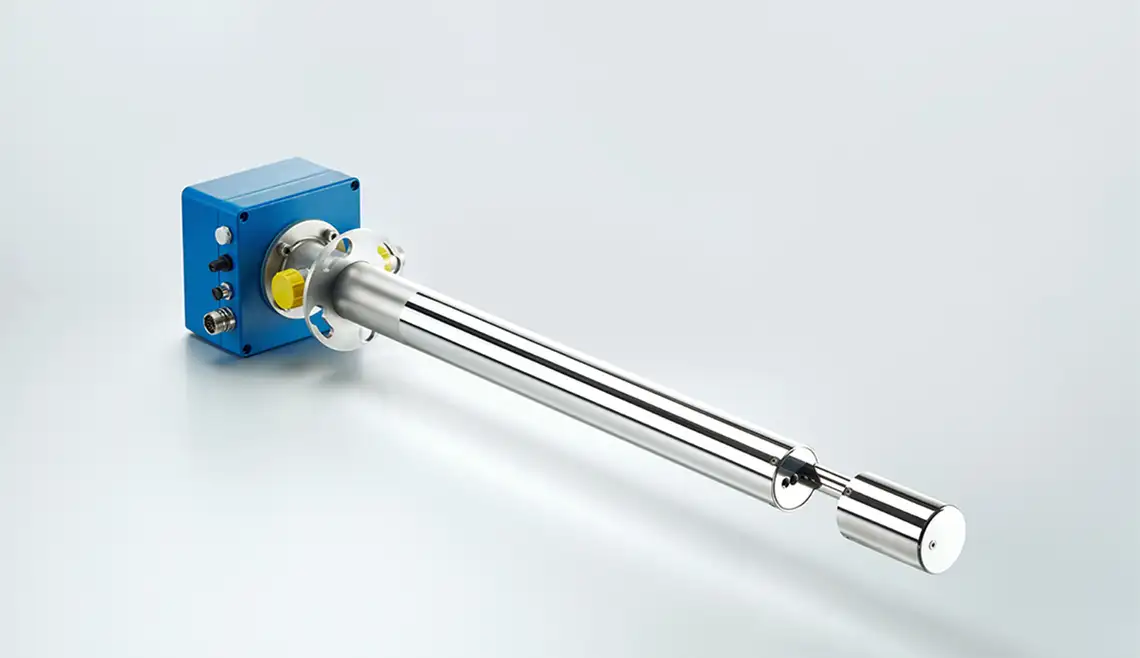

DURAG dust and opacity monitors operate on the basis of the transmission principle. The measurement is performed continuously in the flue gas stream above the dew point without contact and without extracting a sample. The measuring head (sender and receiver) and the reflector are fitted opposite each another. By using the auto collimation principle, the measuring light crosses the measuring path twice and the measurement sensitivity is doubled.

Open video in full screen mode

Scattered light principle: Forward scattering

We use a third party service to embed video content that may collect data about your activity. Please review the details and accept the service to watch this video.

This type of DURAG dust monitor is based on the forward scattering principle and is suitable for monitoring small to medium dust concentrations. It is mounted one-sided at vertical or horizontal oriented stacks, where the probe is in direct contact with the flue gas.

A red laser irradiates the dust particles in the measurement volume of the flue gas duct with modulated light. The light scattered by the dust particles in the forward direction is collected by a lens and then guided to a highly sensitive detector by an optical waveguide. The detector measures the scatter on the basis of the reflection and refraction of the light by the dust particles. If the wavelength of the incident light is much larger than the diameter of the particle, so-called Rayleigh scattering occurs. If the wavelength is about the same size as the diameter of the particles, Mie scattering will occur. The greater the particle size, the more light is scattered in the forward direction.

Scattered light principle: Backward scattering

We use a third party service to embed video content that may collect data about your activity. Please review the details and accept the service to watch this video.

This type of dust monitor is suitable for monitoring low to medium dust concentrations. The measurement is performed continuously above the dew point in the flue gas stream without contact and without extracting a sample. The light from a red laser diode illuminates the dust particles in the stack and is scattered by the particles. The light scattered backwards by the dust particles is detected using a highly sensitive photodiode.

The ratio of the measured scattered light intensity and the emitted light intensity correlates to the particle density in the measurement volume and is measured by the monitor as a scattered light unit. The measurement volume is defined through the intersection of the laser beam sent and the receiving aperture of the detector. The intensity of the scattered light is a function of the scatter angle, the particle size, the wavelength of the incoming light and the optical properties of the particle, such as color and shape or refraction index.

Extractive measurement

We use a third party service to embed video content that may collect data about your activity. Please review the details and accept the service to watch this video.

Continuous dust monitoring in wet or humid flue gases requires a special dust monitoring system. The sample needs to be prepared to remove liquids which also scatter light but do not correlate to dust concentration. In extractive measurement, the probe is located inside the stack. The sample is heated up and can be diluted. The dry sample then passes through a measuring cell where the forward scattering principle is applied. The signal resulting from the scattered light detector is a measure of the dust content of the flue gas. The sample is finally transferred back into the stack.

Industrial applications of dust monitoring

DURAG dust measurement systems are used in a wide range of industries, including power generation, cement production, waste incineration, metallurgy, chemicals, and pulp and paper. Typical applications include emission monitoring in stack gases, process control after filtration units such as electrostatic precipitators or fabric filters, and monitoring of dust-laden gas flows in drying or cooling processes.

Each of these industries presents specific challenges for dust monitoring. High temperatures, aggressive or corrosive gases, varying particle sizes, and fluctuating dust concentrations place heavy demands on the measuring systems. For example, waste incineration and cement plants often require rugged, low-maintenance systems that deliver stable results even under extreme and changing conditions. In the power and steel industries, reliable performance in high-temperature ducts and the ability to detect small changes in emission levels are crucial.

To meet these diverse requirements, DURAG offers a broad portfolio of dust measurement technologies – including systems based on transmission principles, forward scattering, backward scattering and extractive measurement. Depending on the application, systems are available with various certifications (e.g. QAL1), probe lengths, purge air options, and materials designed for resistance against high temperatures or chemically aggressive environments. This modular and application-specific approach ensures optimal measurement performance and long-term stability across all industrial sectors.

Case studies and key applications at a glance

Continuous emission measurement in sugar factory with coal-fired boiler

Emission Monitoring Refinery

Emission analysis on islands in the Caribbean and the Indian Ocean

Power Industry

Cement Industry

Steel Industry

Petrochemical Industry

Waste Incineration

Continuous Emission Monitoring Systems (CEMS)

The importance of dust monitoring in emissions control

In industrial plants, dust monitoring is essential for controlling emissions directly before they are released into the atmosphere, usually within flue gas ducts or stacks. By continuously measuring the dust concentration in these exhaust streams, operators can ensure that filtration systems are working effectively and that legal emission limits are being reliably observed.

If dust emissions are not controlled at this stage, it can lead to non-compliance with environmental regulations, increased wear on downstream components and pose risks to occupational safety within the facility. Furthermore, exceeding permitted emission values may result in fines, operational restrictions or reputational damage.

As a leading provider of certified dust measurement technology, the DURAG GROUP offers robust and precise solutions for the continuous monitoring of stack emissions in industrial exhaust gases. Our systems are designed for long-term use in challenging environments, supporting the safe, compliant and efficient operation of your plant.

Your DURAG benefits at a glance:

- Reliable compliance with legal emission limits through precise and continuous measurement

- Early detection of filter malfunctions and process deviations to prevent unplanned downtime

- Robust technology for long-term use even under harsh conditions such as high dust load or elevated temperatures

- Minimized maintenance effort thanks to low-maintenance sensor technologies and automated control functions

- Flexible application with certified systems for various measurement principles (e.g. scattering light) and industries

- Seamless integration into higher-level control systems for complete emissions documentation and efficient process management

This might also interest you

Filter Monitoring

Volume Flow Measurement

Continuous Mercury Monitoring and Analysis

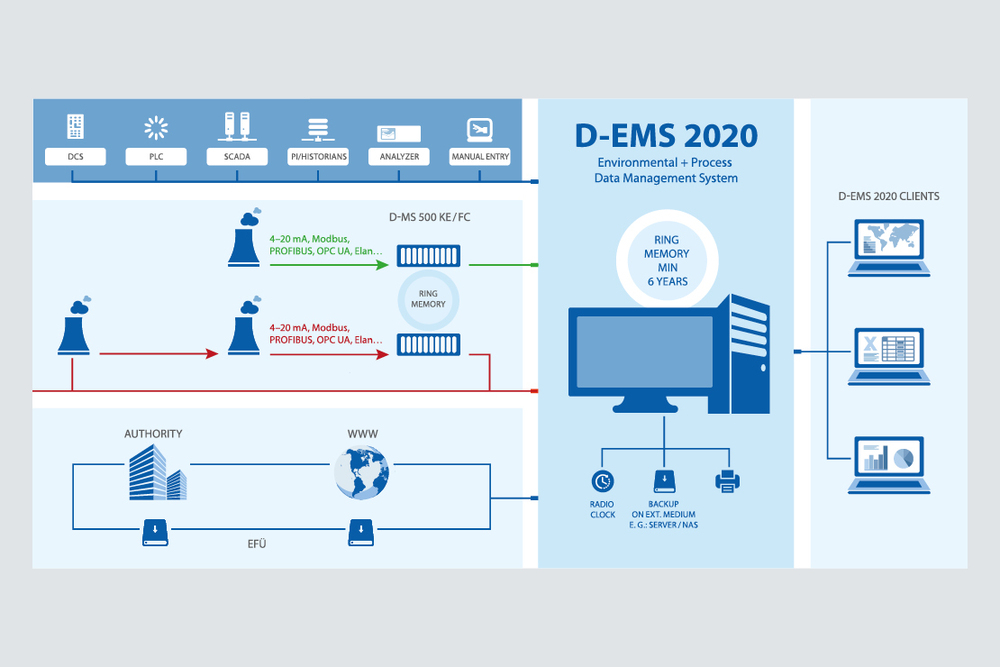

Environmental and process data management | Emission and raw gas